Chemical Injection Applications

Chemical injection systems alleviate specific downhole problems efficiently with minimal operating costs by injecting chemicals at a controlled rate, directly to the source of the problem. In past practices, downhole chemicals were utilized by batching them down the casing or using continuous backside injection, which can be an expensive, wasteful process and ineffective as controlled chemical injection.

The use of a chemical injection system along with an artificial lift system such as ESP or PCP can offer a reliable and economical solution to downhole issues. Chemical injection lines can be reused multiple times and moved to different well sites. We have supplied chemical injection systems for many different applications and successfully improved the rate of production for our customers.

By accurately injecting chemicals down a capillary string to the root of the problem, we will reduce your chemical consumption by roughly 80%, versus batching down the casing or continuous backside injection. This will increase the life expectancy of your artificial lift equipment and maximize production, reducing your lifting costs at the wellhead.

Accurate Chemical Delivery Benefits

- Inhibits paraffin, scale, and asphaltene build-up in oil and gas wells

- Routes corrosion inhibitors to the base of an artificial lift pump to prevent corrosion issues

- Reduces scale in coal-bed methane or water well projects

- Injects H2S scavenger downhole to sweeten a well to meet pipeline specifications

- Prevents internal ice plugs in deep producing gas wells

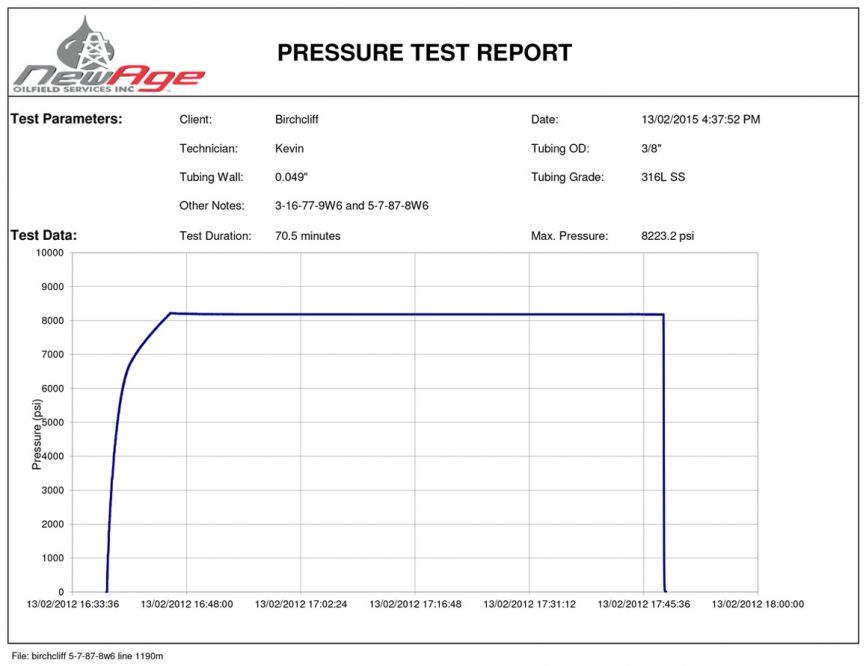

New Age Oilfield’s expertise allows us to assist in the proper alloy selection for the string and the most suitable downhole components for each specific application. We have detailed procedures and equipment in place for pressure testing capillary lines and related components such as injection subs, check valves, and surface filtration packages for integrity. All tests are recorded as a computerized graph printout showing time versus pressure. This documentation is then provided to the customer.

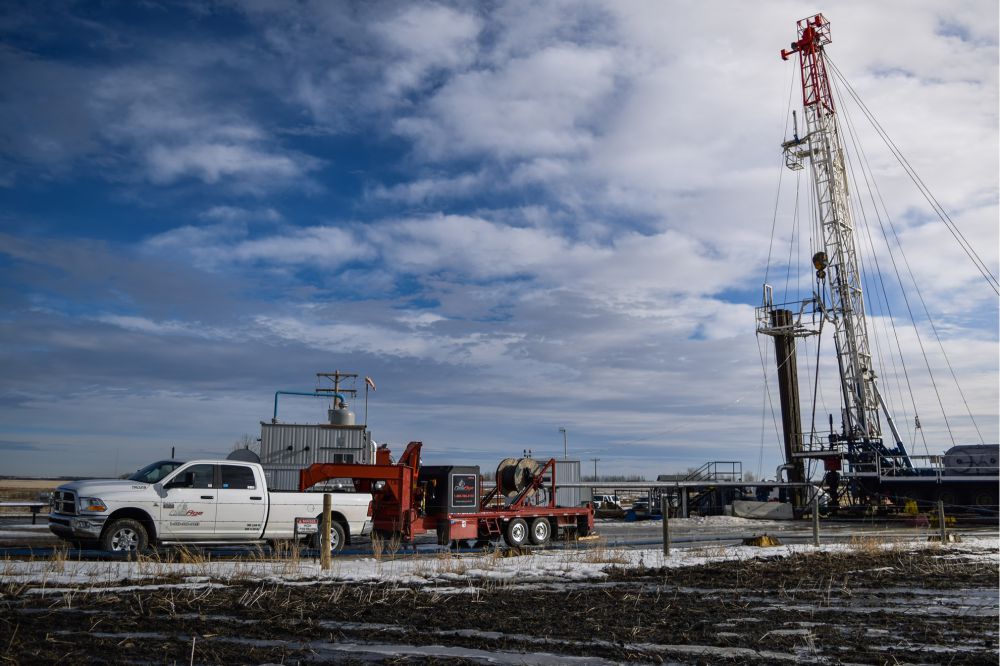

With our chemical injection component inventory and extensive equipment line up, we can supply trailer mounted spooling equipment or full size ESP trucks to spool multiple chemical injections lines simultaneously on its own, or with an ESP cable.

Service Request:

Chemical Injection Install

Capline Install

Chemical Injection will alleviate Paraffin Wax issues

Chemical Injection will alleviate Corrosion issues

Pressure Test Report