Shop Services & Testing

Since 2004, New Age Oilfield’s Leduc area home base has served as the backbone of the company, providing a home for our product lines and reliable support for all of our complementary services. We moved into our new state of the art 25,000 square foot, 3.57-acre Leduc facility in late 2017. At New Age, we are constantly refining our offerings, and the recent move into a larger facility allowed us to reduce our dependence on third parties, add to our growing list of products and services, and create more internal efficiencies passed on to all of our customers in the form of added value.

Current Services

- Custom length spooling

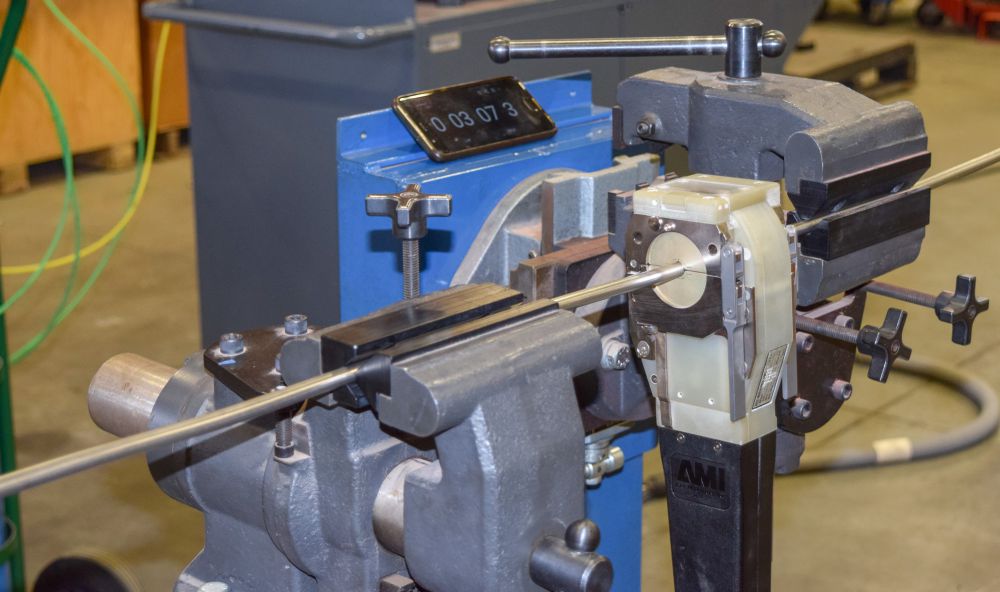

- Capillary tubing orbital welding

- Purging and pressure testing of capillary line and bottom hole assemblies

- Computerized pressure testing with graph printouts

- Refurbishment of bottom hole assemblies, check valves and injection subs

- Clamp fitment testing

- Clamp and cable slippage testing

- Approved Cannon Clamp refurbishment facility

- Cast clamp refurbishment, JHK, LaSalle and others

Clamp Inventory Management

New Age offers clamp inventory management services out of our Leduc facility. With our proven inventory process, we alleviate the risk involved for our customers to manage their clamp inventory. We have dedicated staff and warehouse space for each customer’s new and refurbished clamp products. New Age has the ability to track the usage of each clamp, allowing you to monitor its performance.

We work closely with our customers to assess their clamp requirements, design the product they need, and create inventory levels which meet their requirements.

Contact us for more information on how New Age can lower your inventory risk, costs and warehouse footprint.

Service Request:

Inventory Storage

Pressure Testing

Orbital Welding

Shop Spooling

Check Valve Installation